Fpso Bangka

- Client :- Chevron

-

Project Type :-

Offshore

-

Location :-

Indonesia

Overview

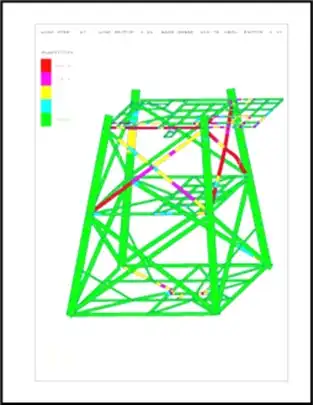

Processing & Facilities Installed

The following major equipment / systems are part of the Bangka topside integration:

- Pig receiver

- Slug catcher

- Inlet heater

- Production separator

- Coalescer separator

- Condensate cooler

- Hydrocyclone unit

| Characteristics |

|---|

Utilities, Control & Safety Integration

- New safety systems: boarding shutdown valves, fire loop‑initiated shutdown, choke valve for manual depressurization, etc.

- Chemical injection systems: such as demulsifier, wax inhibitor, scale and corrosion inhibitor; also MEG (mono‑ethylene glycol) injection for hydrate prevention.

- Metering systems to separately monitor Bangka versus West Seno production. Flow computers for gas & liquids.

| Engineering Services |

|---|

- Overall Project management

- Updated P&IDs, Process Flow Diagrams, and Safety Documents

- Engineering Design Documentation (Basic & Detailed)

- Installation and Hook-up of New Processing Equipment

- Mechanical Completion and Pre-Commissioning

Commissioning and Performance Testing