Biodiesel loading & Unloading facility

- Client :- PT PETROMINE ENERGY

-

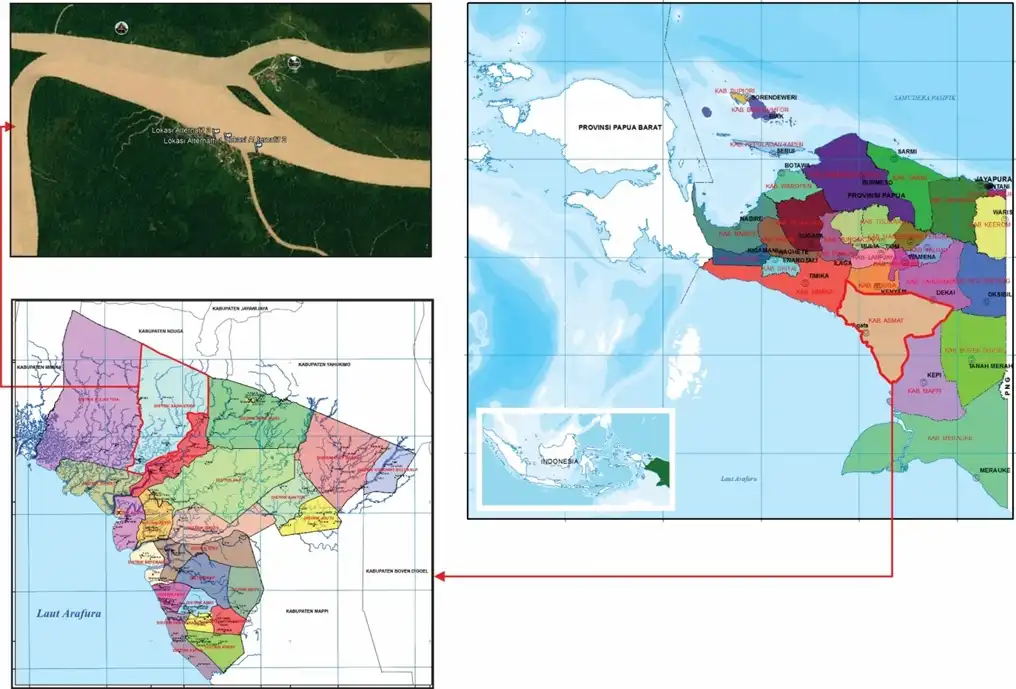

Location :-

Indonesia

Overview

As part of business development strategy, PT Petromine Energy Trading (hereafter called COMPANY) plan to expand the current existing unloading facility (75,000 CBM diesel storage terminal) by constructing the new loading and unloading system, including associated onshore facility at Sangatta, Kutai Timur, East Kalimantan (hereafter called PROJECT)

| Characteristics |

|---|

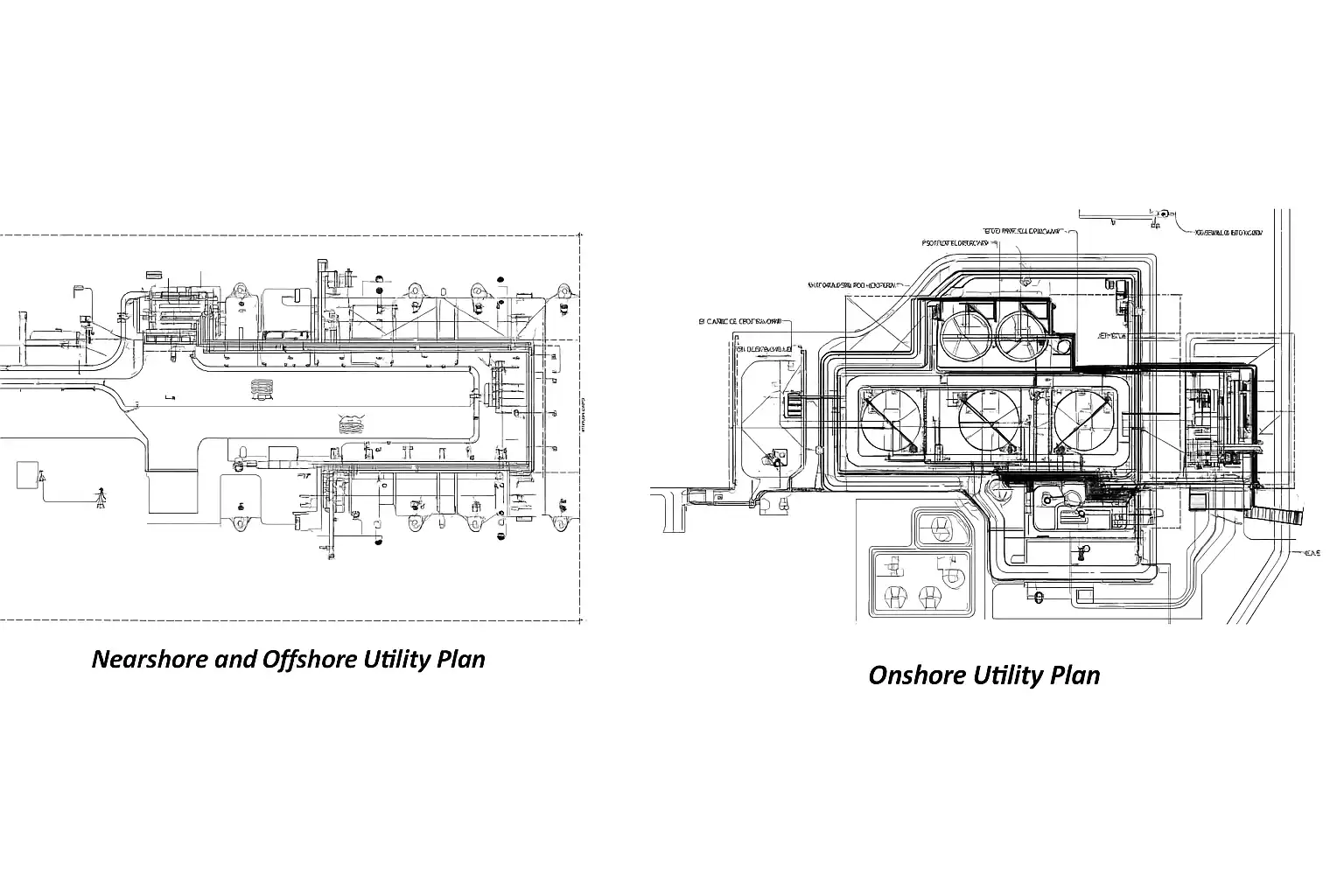

Process & Mechanical Design

▪ Design unloading system (marine hose/arm, pump, pipeline, storage tank)

▪ Select biodiesel-compatible pumps

▪ Design piping, valves, and filters

▪ Prepare PFDs & P&IDs

Civil & Structural Works

▪ Design foundations

▪ Design pipe supports and bund walls

▪ Modify or construct jetty structures where marine unloading is involved

Electrical & Instrumentation

▪ Provide power systems for pumps and lighting

▪ Install flow, level, and pressure instrumentation

▪ Implement automation systems

▪ Provide SCADA and safety interlocks

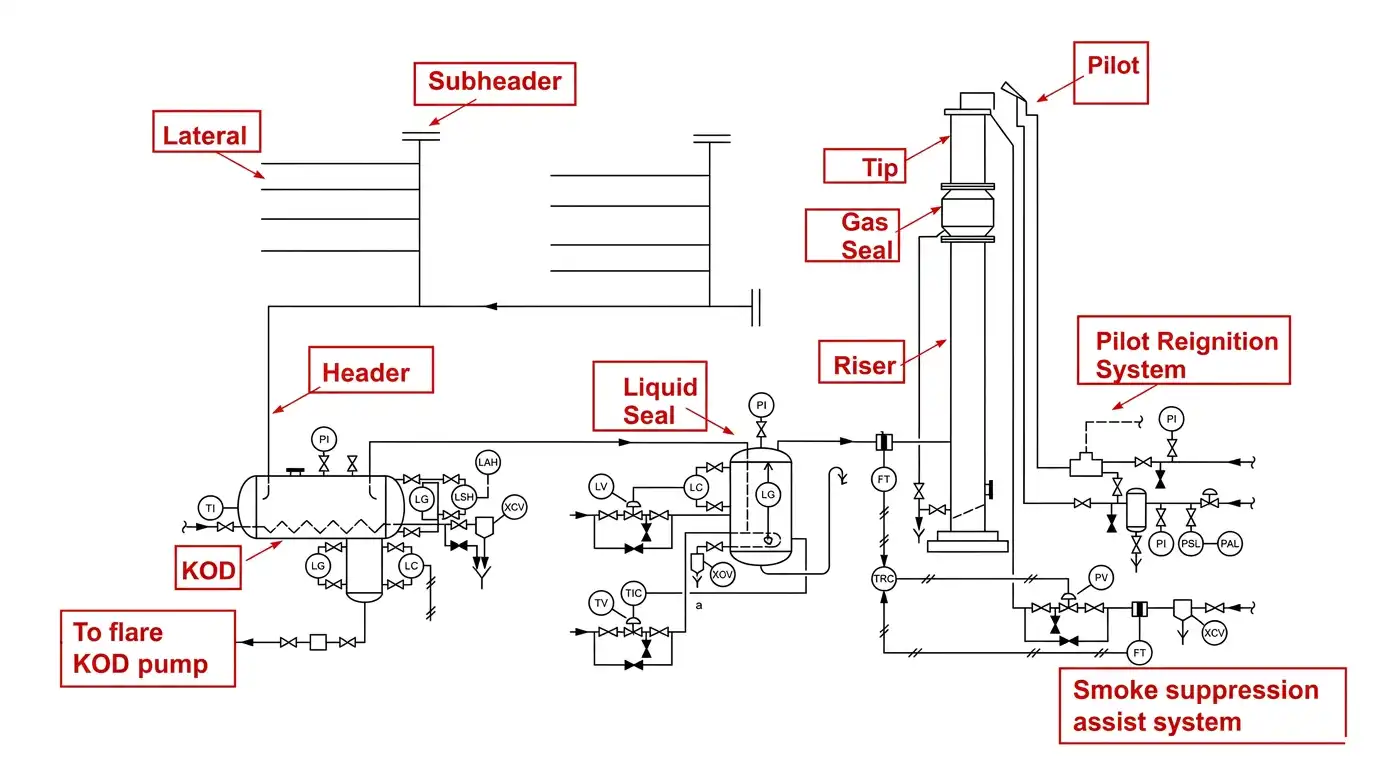

Fire Safety & Environmental Protection

▪ Design fire suppression systems (foam/water)

▪ Provide spill containment and drainage systems

▪ Design tank venting with vapor control

Construction & Commissioning

▪ Execute pipe and pump installation with civil works

▪ Carry out testing

▪ Perform calibration and trial runs

▪ Complete handover with operator training